To see craft skills at work on an industrial scale, visit a factory in London that employs 30 skilled brazers who make the frame of a Brompton bicycle by hand.

If you are the lucky owner of one of these famous folding bikes, have a close look at your frame to see the initials of the person who brazed each of the seams.

I learnt all about the production and history of this bike – which has taken me to and from work in London for years now – on a tour of the factory in Greenford, a rather unexciting suburb in London’s north west.

It is said that in the past 15 years every one of the British prime ministers visited the factory at least once. Brompton is after all one of the UK’s export success stories and makes for a terrific backdrop for a prime minister wishing to be seen with actual working people who are looking like working people.

The bike was invented by Andrew Ritchie in 1975 working up prototypes in his living room overlooking the Brompton Oratory in South Kensington – hence the name. The company has grown hugely since proper production began in the 1980s but remains privately owned.

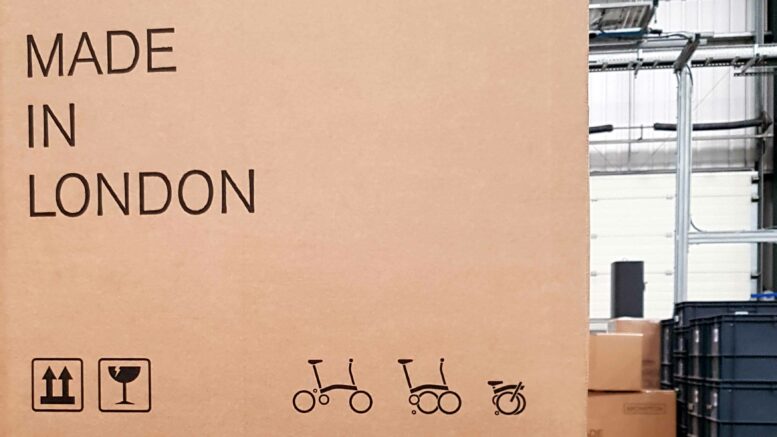

The Brompton is such a success because it is extremely sturdy, not too heavy, and foldable into a very small package. A rarity, it can claim to be ‘Made in London’ as well as ‘Handmade’.

Some 80% of the 50,000 bikes produced every year is exported. The main market nowadays is Japan, followed by Korea, the Netherlands and Germany.

On my tour, a couple from the US talked about their love for their Brompton as it can be stored on their boat. A French student asked a lot of detailed questions because he is working on a university thesis on the international development of the Brompton company. And my own interest was for the next-generation Brompton that includes a small but powerful electric motor. It is those hills in north London that would be so much easier.

But to return to the specific skill that all of the 30 brazers require. It takes Brompton 18 months to fully train one of them. These men and women need to learn to heat up the steel parts that are to be joined just right, and learn how to apply the brass wire around the seam and along the seam. It takes practice to get good at that. That’s why every seam is signed.

And here you see one of the brazers in action.